Project Portfolio

Full Project Portfolio

Click the button on the right to download and open a PDF of our full project portfolio.

Our latest projects are shown below.

Project Case Study #1

C334 & C335 slurry return area

Stainless Steel Retractable return idler frames

Client: NQBP

Task: Site measure, Design, Draft, Construct and Install on site.

Comments: Client requested a method of changing out the idler rolls where the belt could not be lifted due to the slurry return discharge tray above the belt. We designed an assembly that would retract and come away from the belt making it easy to slide out, to allow the idler roll to be changed out. The frame can be secured once extended for extra safety and security of the frame. The entire assembly is constructed from Stainless Steel Gr316. This was submitted for approval then constructed. All design, construction, paint and installation were to NQBP standard off shore specification and Australian Standards.

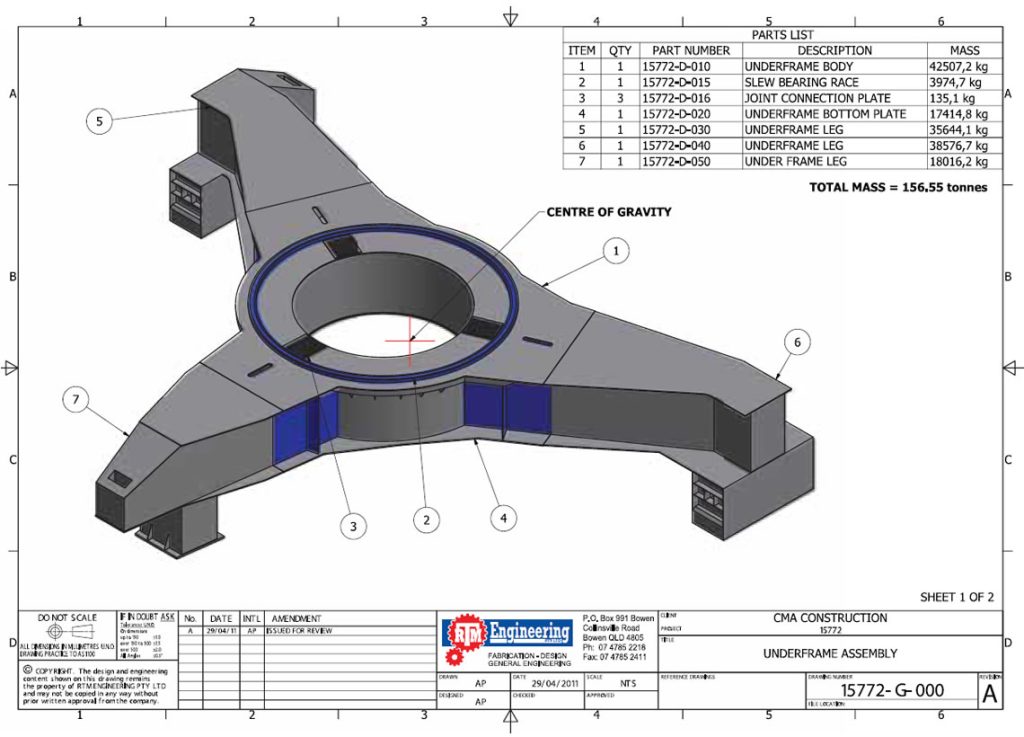

Project Case Study #2

Stacker Reclaimer 2 – Demolition

Client: CMA Construction (NQBP subcontractor)

Task: Site measure, Draft, Design, certify, weld on lugs, NDT of lugs, site welding of support structure

Comments: : CMA needed RTM at short notice to design lifting lugs and the temporary support struts for the removal of the centre section of SR2, this was all to complete their lift study and satisfy NQBP requirements and 3rd party consultant engineer. The weight and centre of mass were calculated by redrawing the entire section in 3D with Inventor, this then allows an accurate mass and centre of gravity to be calculated by the software. This proved critical in the placement of the lifting lugs as the centre section was not symmetrical in any way. The positioning of the lugs allowed for an even lift of the 157 tonnes. Along with this all the required structural supports for the bogie frames were also calculated. We reused steel sections from tripper car for these braces and the counter weights for restraint points. All design and construction were in accordance with Australian Standards.